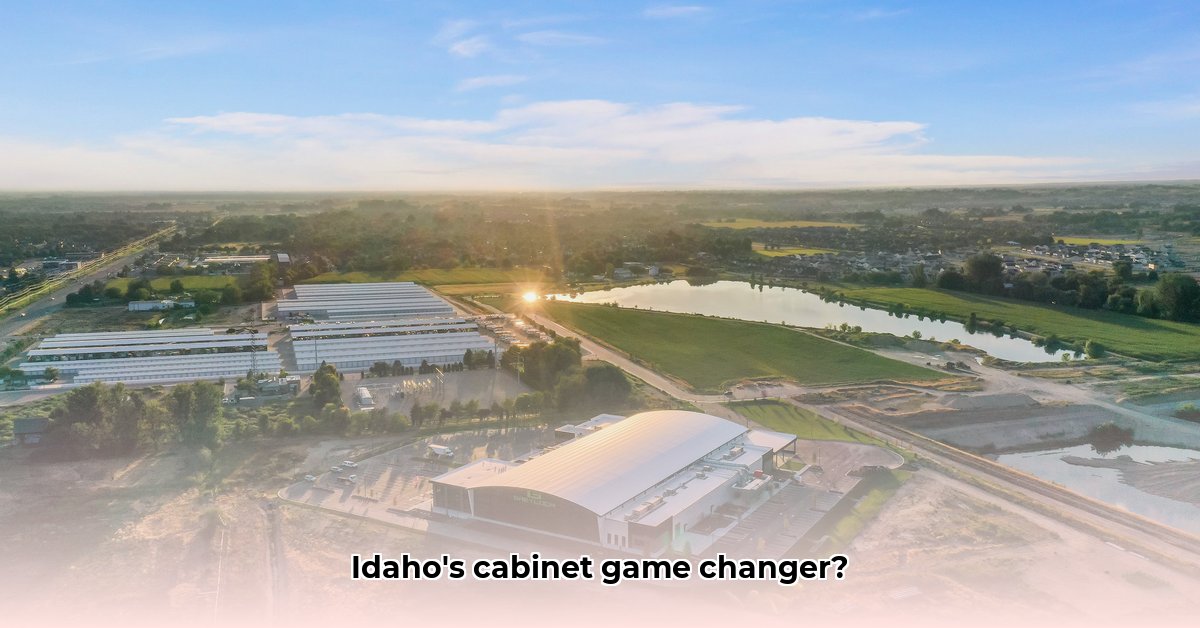

Greyloch LLC's new state-of-the-art cabinet manufacturing facility in Star, Idaho, represents a $44 million investment revolutionizing the custom cabinetry industry. This facility produces approximately 300 cabinets per eight-hour shift—a tenfold increase in production capacity compared to similar businesses in the region. This article provides a technical overview of the facility's automation, highlighting its competitive advantages and future outlook.

The Technological Foundation: Homag Automation and Precision

Greyloch's remarkable production output stems from its sophisticated automated system, primarily leveraging Homag technology. Central to this system is the Homag Sorteq, a highly automated production line capable of processing 2,500 individual cabinet parts during a single eight-hour shift. This integrated system meticulously manages each stage of cabinet production, from precise cutting and edging to accurate drilling and gluing. The result is a significant increase in speed and efficiency, coupled with exceptional accuracy. The system's precision extends to material usage; offcuts (leftover pieces) are cleverly reused, minimizing waste and maximizing material yield. Rigorous quality control checkpoints are integrated throughout the production line, ensuring that every finished cabinet meets Greyloch's exacting standards. How does this level of precision impact production rates compared to traditional methods? The answer is a 10x production increase, a testament to the power of automation.

Competitive Advantage: Speed, Quality, and Market Positioning

Greyloch's competitive edge transcends mere speed; it encompasses quality and market positioning. While competitors may struggle to match their production volume, Greyloch focuses on high-end, frameless European-style cabinets and modern slab panel products, utilizing premium materials and components like high-quality drawer slides and hinges. This strategy allows them to command premium pricing while maintaining superior production efficiency. The combination of high-speed automation and a focus on premium products allows Greyloch to successfully capture a significant market share. Is this strategy sustainable in light of potential competition? The company's proactive risk mitigation strategies suggest it is.

Challenges and Future Outlook: Adapting to a Dynamic Market

While Greyloch currently holds a dominant position, maintaining this leadership requires continuous adaptation and innovation. The inherent risk of technological obsolescence demands proactive mitigation. This includes ongoing investment in Research and Development, exploring new product lines to meet evolving consumer preferences, and possibly incorporating customizable design options. Further challenges include potential supply chain disruptions and equipment malfunctions.

Proactive Risk Mitigation

Greyloch has implemented various strategies to mitigate these risks:

- Equipment Malfunctions: A comprehensive preventative maintenance program, robust service contracts, and redundant systems ensure continuous operation.

- Supply Chain Disruptions: Diversified sourcing, long-term supply contracts, and strategic inventory management minimize the impact of potential shortages.

- Technological Obsolescence: Continuous R&D investment, proactive equipment upgrades, and a flexible facility design enable adaptation to technological advancements.

- Increased Competition: A strong marketing strategy highlighting Greyloch's unique value proposition, coupled with continuous product innovation and strong customer relationships, will ensure market dominance.

Conclusion: Idaho's Cabinet Revolution Continues

Greyloch LLC's new facility represents a significant advancement in Idaho's cabinet manufacturing sector. The integration of Homag's cutting-edge automation has resulted in unparalleled production efficiency and superior product quality. However, their long-term success depends on continuous adaptation, innovation, and a proactive approach to managing risks. Greyloch’s story serves as a model for the future of custom cabinetry, demonstrating the transformative power of advanced manufacturing technologies. This high-tech approach is setting a new standard for the industry, paving the way for sustained growth and innovation in Idaho.